Carbon fibre restoration techniques

Among a musician’s worst nightmares must be one of irreparable damage to their instrument or bow. The restoration of fine bows using carbon fibre reinforcement is a modern technique being researched at The Bow Business. In this way, high quality bows which have been severely damaged may be returned to playing order.

Sometimes we see a bow which has a short crack going through the stick, for which the only traditional repair would be some form of splice using a section taken from another, similar bow. The Bow Business can often restore these bows without splicing them, and give people the chance to keep using their beloved bow, or allowing people to purchase restored high quality bows at a reasonable price.

Here's where we get technical!

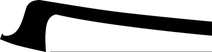

I use a variety of techniques in my restoration work, both traditional and modern. Recently, I restored a cello bow made by Georges Leon Lamy, son of the famous Alfred Lamy. The cello bow had broken straight across the stick just behind the head (see photo above), making it impossible to restore by the simple methods of gluing and binding with silk thread. Instead, I fitted a carbon fibre ‘spine’ across the break in the stick. There was also a crack in the head itself, which required a separate repair using a standard pernambuco spline.

You may be interested to read this summary of my technique:

1 The head was glued in place.

2 The bow was set in plaster of Paris to hold it absolutely steady for the next part of the process.

3 The whole assembly was mounted on a lathe and a channel was milled out along the top of the stick.

4 A carbon fibre rod of exactly the same dimensions was fitted into the channel.

5 The carbon fibre was filed flush with the stick.

As there was further damage to the head, the crack was glued and a reinforcing spline of pernambuco was fitted along the centre line of the head and into the carbon fibre.

Many bow restorers would not approve of this repair technique. There is an older method which involves splicing a new piece of wood across the damaged area and then fitting the lower portion of the head onto the new wood and reshaping the repaired area accordingly. So why use carbon fibre if there are traditional ‘pure wood’ repairs which would also work? Well, in my opinion, the carbon fibre technique is at least as good - and possibly better - for the following reasons:

Firstly, the bow is still made from just one bow, it doesn’t require having another bow to cannibalise to make the restoration.

Secondly, it involves the minimum removal of original wood

Thirdly, no one is left in any doubt that the bow is still the same length as it was originally, or that the head shape is exactly right, or that it has the same camber etc. This is because the stick remains almost 100% complete.

In my experience, carbon fibre inserts are incredibly strong, in fact probably stronger than the wood itself. It is also a similar weight to the pernambuco it replaces, and is flexible enough to allow the stick to flex as it should.

But back to the George Leon Lamy cello bow!

The first person to try it out emailed me and said:

'...It is amazing!! I absolutely love it. It's hard to put it down.... I ended up doing the concert with it and it felt so good.'

(Her concert included a Brahms piano quintet, so quite a rigorous test for the repaired bow.)

And then, as if to prove a point, she bought it!

And why shouldn’t we be open to new materials and new techniques? Let’s face it, these days we have embraced synthetic strings, electric instruments and carbon fibre bows so it is inevitable that new technology and new materials used in making music will also become available to the restorer. The use of these materials must be subject to the traditional ethical concerns that any conservator or restorer faces to help us choose the most appropriate technique.

Here at The Bow Business, I want to be open to new techniques, to restore damage bows, and get them back into good playing order. If you have a bow which you think may be a write-off, why not get in touch and let me see if I can help?